"Panel Semiconductor" is an unprecedented concept invented by Innolux. Advanced packaging technologies which highly integrates chips is an important direction for Innolux to cross the border and enter the realm of semiconductor development. Innolux has also joined hands with partners such as IC Design House and OSAT to carry out technological innovation with heterogeneous integration.

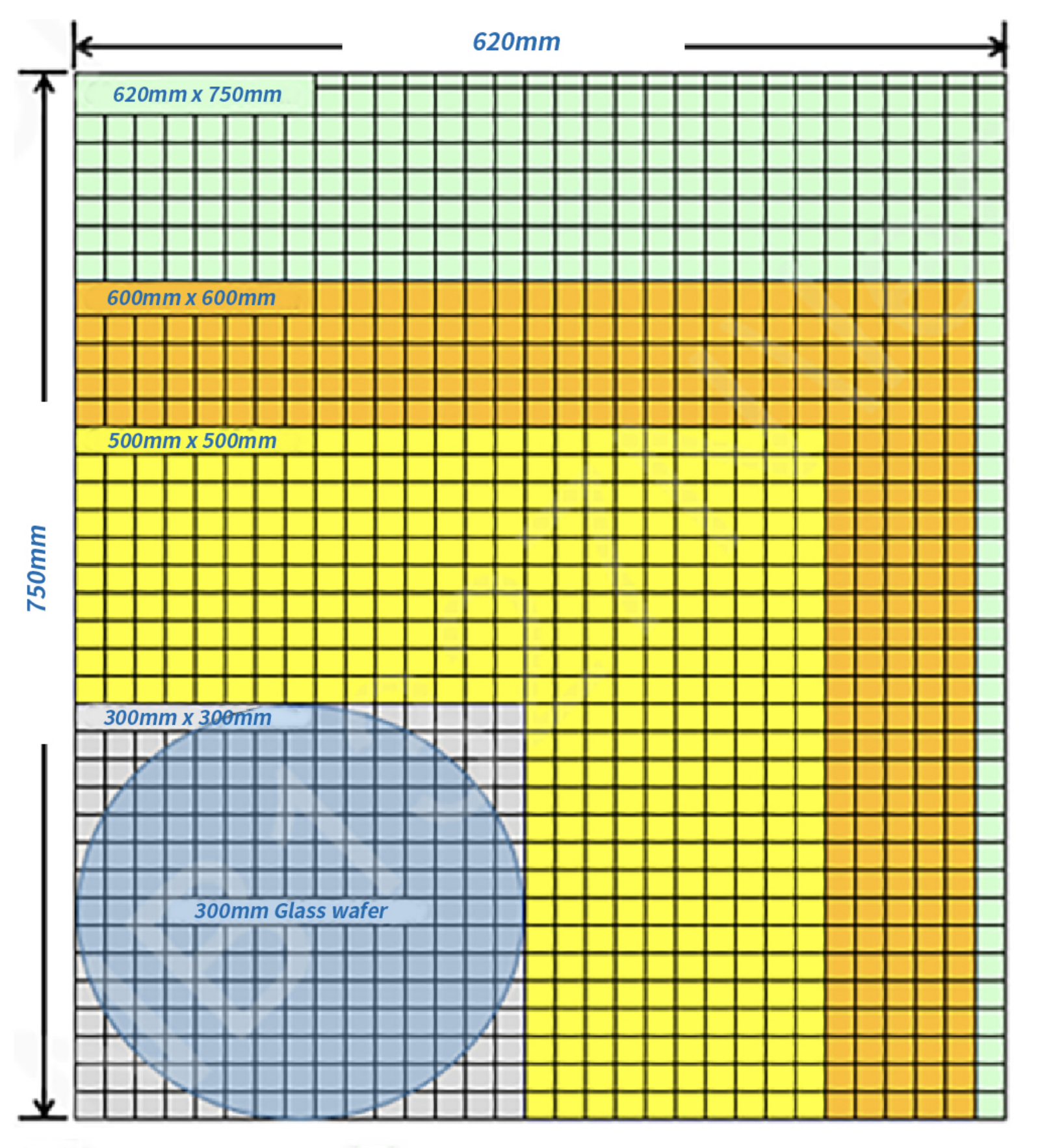

Innolux will first activate its existing G3.5 production line. It intends to develop mid-to-high-end semiconductor packaging with line widths ranging from 2μm to 10μm using the industry’s largest G3.5 FOPLP (620mm X 750mm) Glass Panel, whose area is 7 times (as shown in the picture below) that of 300mm Glass Wafer. Currently, the Warpage problem has been overcome in the FOPLP technology development. With the high glass utilization rate of the square shape, Innolux’s development looks to take advantage of "accommodating more I/O," "smaller size," "more powerful performance," "saving power consumption," etc., further provide more competitive costs, and create greater value.

In the future, Innolux aims to engage in the integration of FOPLP and automotive display panels, and to broaden its horizons through vertical integration of the supply chain.

G3.5 FOPLP Glass Panel production area